Engineering & Design

We're experts in the value-added engineering and design

of complex projects and will find creative and

practical solutions to fit your requirements.

of complex projects and will find creative and

practical solutions to fit your requirements.

Engineering & Design

Specializing in complex engineering projects

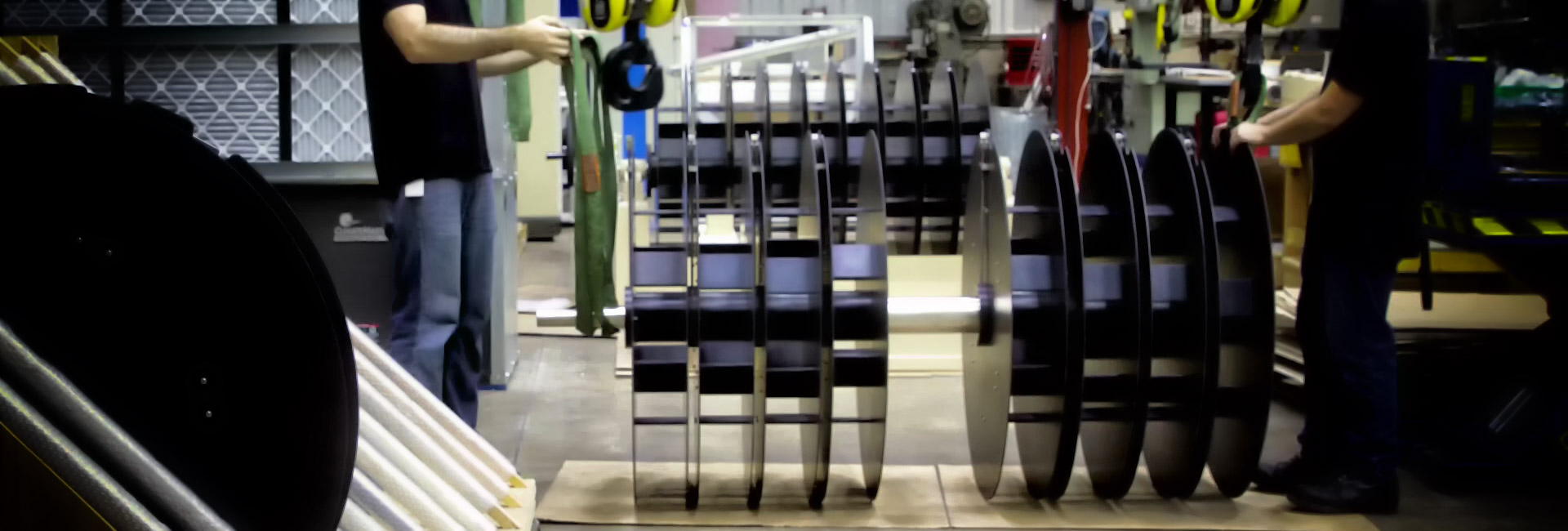

Fabrication

Sheet Metal, Tube, and Pipe Fabrication.

Today's technology combined with

hands-on engineered solutions will

help to meet your fabrication needs.

Today's technology combined with

hands-on engineered solutions will

help to meet your fabrication needs.

Fabrication

Water jet & laser cutting, bending, rolling & punching

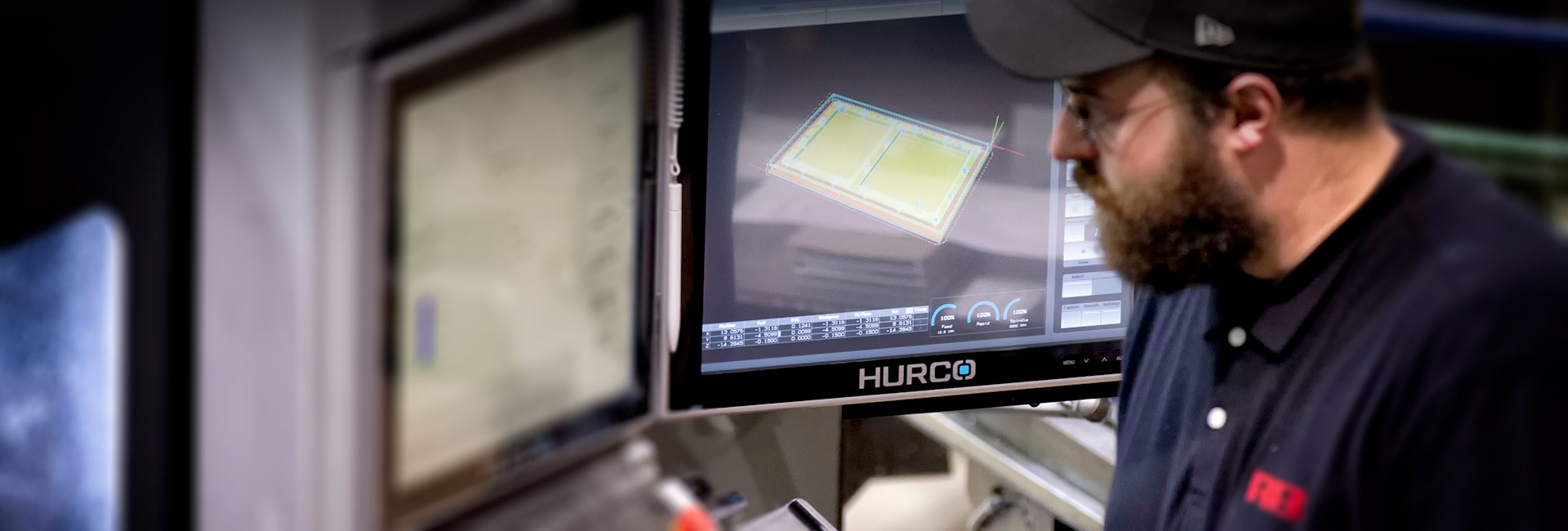

Machining

Precision CNC Machining is the only way

to ensure parts can meet high tolerance

requirements. Let us machine your ideas

into a tight toleranced reality.

Machining

Vertical / Horizontal Multi-Axis CNC Milling, turning & drilling

Welding

Welding is an art.

We don’t have welders...

we have artists with

over 200 years of experience.

We don’t have welders...

we have artists with

over 200 years of experience.

Welding

GTAW/TIG, GMAW/MIG, ERW, EB, brazing & soldering

Finishing & Processing

The finish of your order is as important

to us as the design and machining.

We ensure all your finishing requirements

will be certified to your specifications.

to us as the design and machining.

We ensure all your finishing requirements

will be certified to your specifications.

Finishing &

Processing

Processing

Blasting, heat treating, plating, painting & marking